Who is online?

In total there are 4 users online :: 0 Registered, 0 Hidden and 4 Guests None

Most users ever online was 112 on 8th October 2020, 7:09 am

Latest topics

» Champion the Lumber Horseby Chilli-head 18th August 2024, 6:24 pm

» Hungry Birds

by Dirick55 7th December 2023, 6:04 am

» PRESENTATION

by Chilli-head 23rd November 2023, 2:55 pm

» New Kiva loan

by Chilli-head 21st July 2023, 12:35 pm

» A peat-free compost is top in UK Which? magazine trial

by Dandelion 25th April 2023, 9:42 pm

» New gardening year 2023

by Chilli-head 5th March 2023, 10:15 pm

» What have I done in the workshop today?

by Dandelion 2nd December 2022, 1:12 pm

» What are you harvesting today?

by Dandelion 2nd December 2022, 1:12 pm

» Wartime marrow casserole

by Dandelion 18th October 2022, 4:42 pm

» Late sowings in August ... beans ?

by Ploshkin 11th August 2022, 9:29 am

» Come August, come night in the garden

by Chilli-head 4th August 2022, 3:29 pm

» Welcome guest

by Ploshkin 31st July 2022, 9:16 am

» The Jolly July Garden

by Ploshkin 19th July 2022, 11:38 am

» More mead ...

by Chilli-head 13th July 2022, 12:52 pm

» The June garden thread

by Dandelion 25th June 2022, 9:55 pm

» Plastic bags

by Dandelion 5th June 2022, 7:28 pm

» The merry May garden

by Dandelion 31st May 2022, 10:04 pm

» Fooling around in the April garden

by freebird 1st May 2022, 8:33 am

» March into the garden

by Dandelion 1st April 2022, 7:26 pm

» Mow Suggestions

by freebird 29th March 2022, 5:48 pm

Statistics

We have 271 registered usersThe newest registered user is Phil Morris

Our users have posted a total of 48047 messages in 2416 subjects

Similar topics

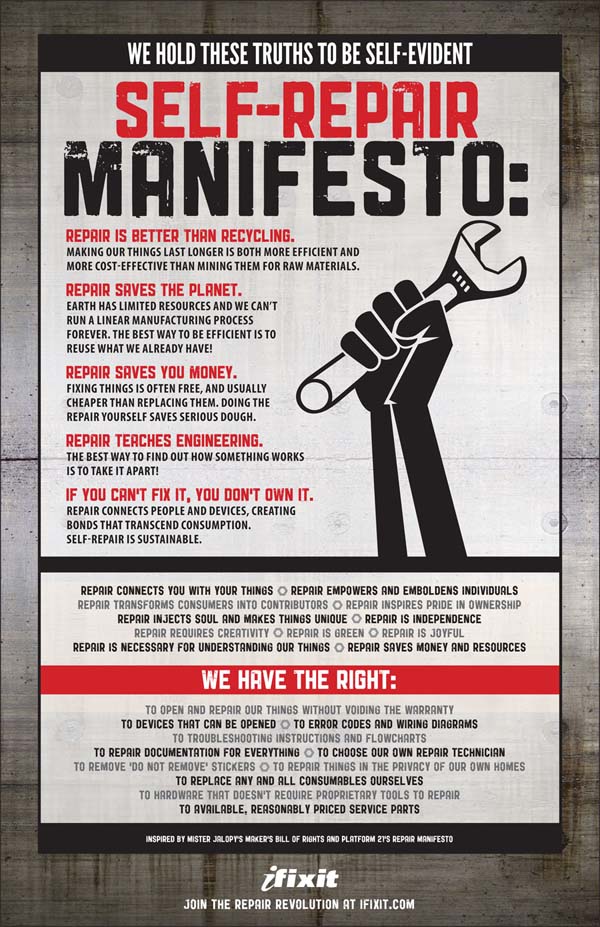

The Self Repair Manifesto

+6

Hairyloon

Dandelion

bronze

mr_sfstk8d

Sparhawk

Adrian

10 posters

Page 1 of 1

Re: The Self Repair Manifesto

Re: The Self Repair Manifesto

One printed to go in the kitchen tomorrow, I'm sure more will follow...

Thanks...

Sparhawk- Posts : 1787

Join date : 2009-11-15

Age : 57

Location : Isle of Wight

Re: The Self Repair Manifesto

Re: The Self Repair Manifesto

Absolutely. I particularly like the bit about "if you can't fix it, you don't own it."

mr_sfstk8d- Posts : 584

Join date : 2010-12-01

Age : 47

Location : Peoria, IL, US

Re: The Self Repair Manifesto

Re: The Self Repair Manifesto

sounds wonderful and idealistic but

I can't mend the glass in my specs does that mean I dont own them?

I can't mend the glass in my specs does that mean I dont own them?

bronze- Posts : 90

Join date : 2010-11-26

Location : Norfolk

Re: The Self Repair Manifesto

Re: The Self Repair Manifesto

I like the sense of empowerment and responsibility in this. I'm not a natural engineer or mechanic, though I do enjoy understanding how things work. I get frustrated when things are designed badly so that when parts break they can't be repaired. (Our extractor fan in the bathroom broke in the summer - when we took the front off it wasn't possible to do anything about the little bit of plastic which had sheared off. On the other hand it has saved us a bit of money not using electricity to ventilate the room!!)

Dandelion- Admin

- Posts : 5416

Join date : 2010-01-17

Age : 68

Location : Ledbury, Herefordshire

Re: The Self Repair Manifesto

Re: The Self Repair Manifesto

I am not so sure about DIY repairs not voiding the warranty. I depends on the item and the fault, but a bad bodge can make an item much more difficult to properly fix.

Despite that, I am still minded to forward it to my MP.

Despite that, I am still minded to forward it to my MP.

Hairyloon- Posts : 649

Join date : 2009-12-09

Location : UK

Re: The Self Repair Manifesto

Re: The Self Repair Manifesto

bronze wrote:sounds wonderful and idealistic but

I can't mend the glass in my specs does that mean I dont own them?

Well, I don't suppose fabrication is the chief requirement. Many things are rather difficult, if not impossible, to make in the home.

However, I'd say that if you had the new lenses in, if you could remove the screws and set the new lens, that counts

mr_sfstk8d- Posts : 584

Join date : 2010-12-01

Age : 47

Location : Peoria, IL, US

Re: The Self Repair Manifesto

Re: The Self Repair Manifesto

Hallelujah to this. This has long been our mantra - mainly because we come from a time when people DID repair things. Even the boughs for the Christmas wreath were tied in place using gold wire which had criss-crossed a rather nice bottle of Rioca . . . and OH was trying to sort our central heating only yesterday . . . Today it's my turn to patch a pair of trousers . . .

Re: The Self Repair Manifesto

Re: The Self Repair Manifesto

I can't imagine living in any other way tbh!

Compostwoman- Posts : 5688

Join date : 2009-11-08

Built to burn out

Built to burn out

I hate throwing things away, especially after little more than a year or two. But so many power tools are built with obsolescence in mind, especially cheap imports from China.

As we depend on wood for heating and water heating, I thought it was a good idea to buy a large table saw a year ago, but the motor has just burnt out after very little use. The rest of the saw is in good shape, but when I dismantled it, I found there is no obvious way of attaching another motor. The old one seemed to be part of the whole mechanism including a gearing down to make the blade rotate more slowly.

I don't want to give up, but there are 2 hp motors available relatively cheaply which rotate at around 1200 turns a minute, or more expensive ones at 2800 rpm. I've no idea if either the power rating or the rotational speed is adequate to repair my saw with its 250mm blade.

Alternatively I have an ancient saw bench with a very large blade, which used to be powered with a belt from a tractor. Would 2 horse power be enough for that?

As for repairing things, it may be just a mistake to buy another motor which in turn could burn out, while the real solution would be to forget the whole idea and stick with chainsaw technology which is rather more robust.

As we depend on wood for heating and water heating, I thought it was a good idea to buy a large table saw a year ago, but the motor has just burnt out after very little use. The rest of the saw is in good shape, but when I dismantled it, I found there is no obvious way of attaching another motor. The old one seemed to be part of the whole mechanism including a gearing down to make the blade rotate more slowly.

I don't want to give up, but there are 2 hp motors available relatively cheaply which rotate at around 1200 turns a minute, or more expensive ones at 2800 rpm. I've no idea if either the power rating or the rotational speed is adequate to repair my saw with its 250mm blade.

Alternatively I have an ancient saw bench with a very large blade, which used to be powered with a belt from a tractor. Would 2 horse power be enough for that?

As for repairing things, it may be just a mistake to buy another motor which in turn could burn out, while the real solution would be to forget the whole idea and stick with chainsaw technology which is rather more robust.

Re: The Self Repair Manifesto

Re: The Self Repair Manifesto

2HP should be good for most type of sawing conditions. And a speed of 2800 RPM is pretty good too. If you've got a saw of VERY large size, perhaps a higher HP motor should be considered, but then overall RPM will be lower, as the cutting velocity at the tool point is what is considered. With a larger diameter, a lower turning rate gets same tool point velocity. Make sense?

With all this in mind, I think duty rating should be part of your considerations as well. You say that you use wood for many tasks around. Many cheaply built tools and fixtures are intended for only occasional use. Once a month for half hour, say. The difference to the industrial/commercial grade tools is not so much overall power rating and performance specificatons, but duty rating. Perhaps you're looking for something designed for continuous interrupted (1/2 on, half off, all day, every day, passive cooling usually) or fully continuous (full time duty cycle, inboard cooling fan, etc.)

With motors especially, if it's something to get frequent, hard and prolonged use, type of motor bearings is important. Steel bearings, ball bearings, cylindrical bearings good. "Sleeve bearing", which is really just the shaft lying in a brass or aluminum bushing, is cheap and will fail.

With all this in mind, I think duty rating should be part of your considerations as well. You say that you use wood for many tasks around. Many cheaply built tools and fixtures are intended for only occasional use. Once a month for half hour, say. The difference to the industrial/commercial grade tools is not so much overall power rating and performance specificatons, but duty rating. Perhaps you're looking for something designed for continuous interrupted (1/2 on, half off, all day, every day, passive cooling usually) or fully continuous (full time duty cycle, inboard cooling fan, etc.)

With motors especially, if it's something to get frequent, hard and prolonged use, type of motor bearings is important. Steel bearings, ball bearings, cylindrical bearings good. "Sleeve bearing", which is really just the shaft lying in a brass or aluminum bushing, is cheap and will fail.

mr_sfstk8d- Posts : 584

Join date : 2010-12-01

Age : 47

Location : Peoria, IL, US

Thanks for advice

Thanks for advice

Thanks for the advice mr_sfstk8d.

I guess the burning out was my fault as I was using a table saw designed for cutting the odd piece of timber for carpentry work to cut firewood, and I probably over strained the motor.

I think my solution is to get a 2cv (hp) motor with the lower rev. rate and hitch it up experimentally with a belt to both my large and smaller saw. One or the other should work by the sound of it.

I'd guess that the purpose built motor will be more rugged and powerful than the smaller thing built into the table saw.

I guess the burning out was my fault as I was using a table saw designed for cutting the odd piece of timber for carpentry work to cut firewood, and I probably over strained the motor.

I think my solution is to get a 2cv (hp) motor with the lower rev. rate and hitch it up experimentally with a belt to both my large and smaller saw. One or the other should work by the sound of it.

I'd guess that the purpose built motor will be more rugged and powerful than the smaller thing built into the table saw.

Re: The Self Repair Manifesto

Re: The Self Repair Manifesto

My father made his own circular saw which has a 12" blade, and is powered by a motor re-cycled from an office letter opening machine  I would guess that it is no more than 1 hp, but it does the job. The saw has seen 40 years service, and who knows how old the motor is. They certainly don't over spec things like that anymore .

I would guess that it is no more than 1 hp, but it does the job. The saw has seen 40 years service, and who knows how old the motor is. They certainly don't over spec things like that anymore .

Chilli-head- Admin and Boss man

- Posts : 3306

Join date : 2010-02-23

Location : Bedfordshire

Re: The Self Repair Manifesto

Re: The Self Repair Manifesto

No, things anymore are built to just do the job. With failure at a "time to buy a new one" life expectancy built right in.

My dad had built a "home brewed" electric generator. This was just before the Y2K scare everybody had, but we needed one for other reasons, long story. He could order the winding, or "dog house", from the supplier, but there wasn't a sized engine to be found on new market. So, what did we do? We went to the wrecked van lot, and got a Thermo-King motor from a refridgerated cross country delivery van. It's a diesel engine designed to run continuously under load (i.e. the refridgeration equipment originally). We had a local job shop build a frame to suit by dad's plans, and we made the controls, relays, hook up, etc.

My dad had built a "home brewed" electric generator. This was just before the Y2K scare everybody had, but we needed one for other reasons, long story. He could order the winding, or "dog house", from the supplier, but there wasn't a sized engine to be found on new market. So, what did we do? We went to the wrecked van lot, and got a Thermo-King motor from a refridgerated cross country delivery van. It's a diesel engine designed to run continuously under load (i.e. the refridgeration equipment originally). We had a local job shop build a frame to suit by dad's plans, and we made the controls, relays, hook up, etc.

mr_sfstk8d- Posts : 584

Join date : 2010-12-01

Age : 47

Location : Peoria, IL, US

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum